- Shop

- Uncategorized

PDC Bit and Rock Roller Bit

PDC Bit

Polycrystalline Diamond Compact (PDC) bits are advanced drilling tools widely used in the oil and gas industry, as well as in mining and construction. These bits are renowned for their durability, efficiency, and ability to drill through hard rock formations.

A PDC bit consists of a fixed head with multiple PDC cutters. These cutters are made from synthetic diamond and tungsten carbide, providing exceptional hardness and wear resistance. The synthetic diamond layer is bonded to a tungsten carbide substrate, creating a cutting element that can withstand high temperatures and abrasive conditions.

There are two main types of PDC bits: matrix body bits and steel body bits. Matrix body bits are made from a composite material containing tungsten carbide grains bonded with a metallic binder. They are highly resistant to erosion and abrasion, making them suitable for drilling hard rock. However, they are more brittle compared to steel body bits. Steel body bits, on the other hand, are made from high alloy steel and are more resistant to impact loading. They are often used in softer, less abrasive formations.

PDC bits offer several advantages over traditional roller cone bits. They have no moving parts, which reduces the risk of mechanical failure and allows for longer bit runs. The shearing action of the PDC cutters requires less drilling effort compared to the crushing and grinding action of roller cone bits, resulting in higher drilling efficiency and faster penetration rates.

These bits are particularly effective in drilling long, continuous sections of soft to medium-hard formations. They are not typically used in highly abrasive or cemented sand formations, as these conditions can lead to cutter damage and reduced bit life.

Overall, PDC bits are a critical component in modern drilling operations, offering enhanced performance, durability, and cost-effectiveness.

Our Product Range:

- Hybrid Drill Bit

- RC PDC Drill Bit

- Bi – Center Bit

- Steel Body PDC Bit

- Matrix Body PDC Bit

- PDC Core Bit

Click here to Download Catalogue for PDC Bit.

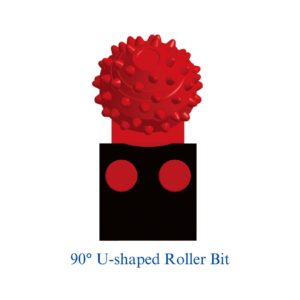

Rock Roller Bit

It is a rotary drill bit that uses two or more rollers to crush the rock formations as it drills into the earth. The rollers are located at the bottom of the bit and rotate on bearings as the drill string turns the bit. The rollers have teeth or inserts designed to grind and break up the rock formations, allowing the bit to penetrate deeper into the earth.

Click here to Download Catalogue for Rock Roller Bit.

- Pickup: Available today at store

- 1 Year Local Official Distributor Warranty